中国龙马溪组页岩气区因其地质历史上多次构造变形而具有独特性。虽然其水力压裂设计经过十年的发展已经成熟,但如果不考虑非均质性,就无法确保每口井的成功。为了应对这些挑战,成立了一个多学科团队来开展工作;经过团队的努力,设计的支撑剂体积实现了套管零变形、更少的漏砂和更弱的裂缝冲击。有效缓解的关键是通过现场数据的持续迭代进行连续的 3D 地质和地质力学 (G&G) 建模。

背景

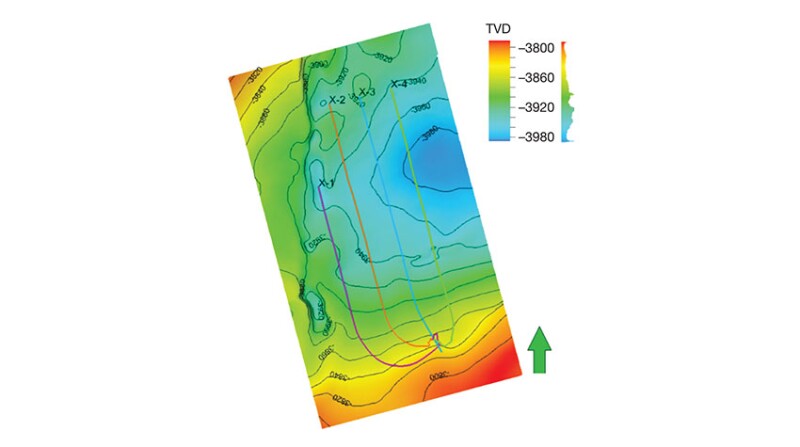

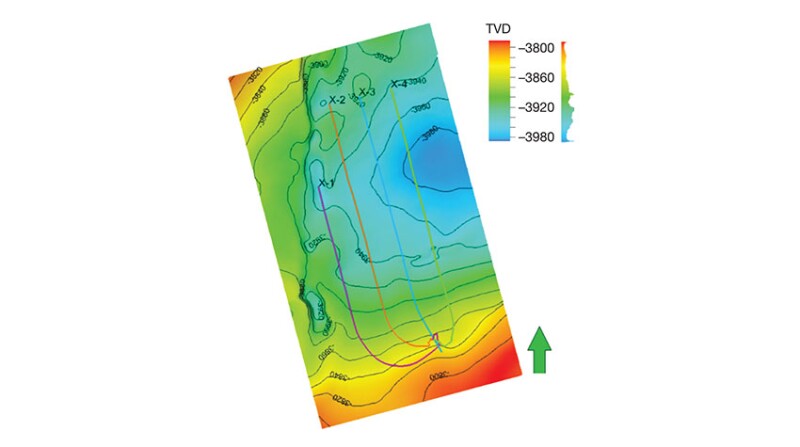

四川盆地龙马溪组页岩储层面积约2万平方公里,埋藏深度在2000~4500m之间。

中国龙马溪组页岩气区因其地质历史上多次构造变形而具有独特性。虽然其水力压裂设计经过十年的发展已经成熟,但如果不考虑非均质性,就无法确保每口井的成功。为了应对这些挑战,成立了一个多学科团队来开展工作;经过团队的努力,设计的支撑剂体积实现了套管零变形、更少的漏砂和更弱的裂缝冲击。有效缓解的关键是通过现场数据的持续迭代进行连续的 3D 地质和地质力学 (G&G) 建模。

四川盆地龙马溪组页岩储层面积约2万平方公里,埋藏深度在2000~4500m之间。

The Longmaxi shale gas play in China is unique because of multiple tectonic deformations in its geological history. While its hydraulic fracturing design has matured after a decade-long evolution, the success of every well cannot be ensured without considering heterogeneity. To address these challenges, a multidisciplinary team was formed to work on a pad; through the team’s efforts, designed proppant volume achieved zero casing deformations, fewer screenouts, and weaker fracture hits. The key to effective mitigation was continuous 3D geological and geomechanical (G&G) modeling through ongoing iterations with field data.

The Longmaxi shale play in the Sichuan Basin is approximately 20 000 km2 and is buried between 2000 and 4500 m.