本研究基于时移应力场、水力压裂模拟、天然裂缝和其他弱界面的综合建模,建立了数值模拟工作流程,以分析页岩气水平井在多级水力压裂过程中的套管变形机理。作者写道,他们的目标是在提高增产效率的同时,指导对套管变形风险的预测并提供缓解解决方案。

介绍

川南地区深层页岩气藏埋深约为3500~4500m,地质条件复杂,断层、裂缝发育,地层水平应力较大,在水平井分段压裂施工中,建立有效的套管变形风险预测方法是一项挑战。

本研究基于时移应力场、水力压裂模拟、天然裂缝和其他弱界面的综合建模,建立了数值模拟工作流程,以分析页岩气水平井在多级水力压裂过程中的套管变形机理。作者写道,他们的目标是在提高增产效率的同时,指导对套管变形风险的预测并提供缓解解决方案。

川南地区深层页岩气藏埋深约为3500~4500m,地质条件复杂,断层、裂缝发育,地层水平应力较大,在水平井分段压裂施工中,建立有效的套管变形风险预测方法是一项挑战。

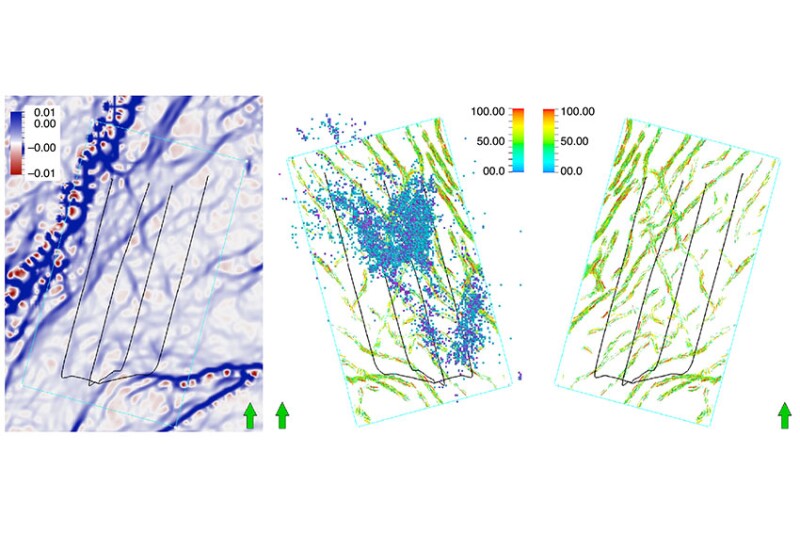

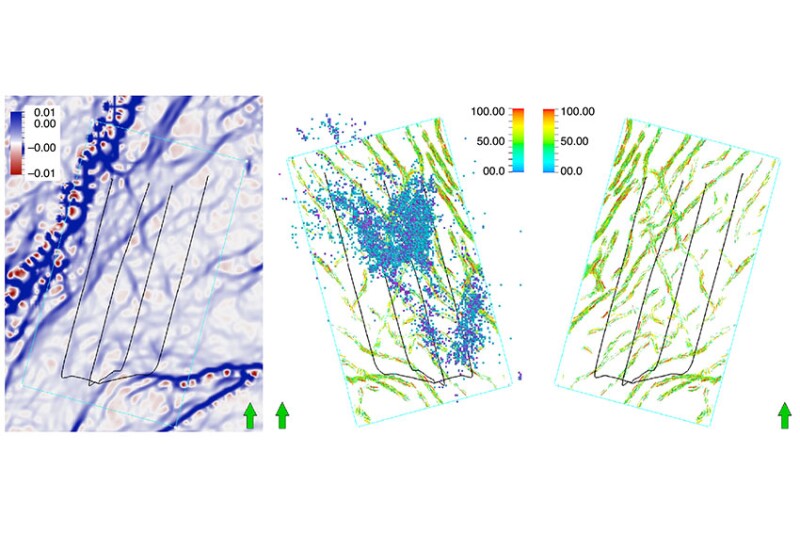

In this study, a numerical simulation workflow was established based on comprehensive modeling of a time-lapse stress field, hydraulic fracturing simulation, natural fractures, and other weak interfaces to analyze casing-deformation mechanisms of shale gas horizontal wells during the multistage hydraulic fracturing process. The authors write that they aim to guide the prediction of, and provide mitigating solutions for, casing-deformation risks while improving stimulation efficiency.

The burial depth of deep shale gas reservoirs in the southern Sichuan Basin is approximately 3500 to 4500 m. These have complex geological conditions with developed faults and fractures and high in-situ horizontal stresses. During multistage hydraulic fracturing operations in horizontal wells, establishing an effective prediction method for casing-deformation risks in these reservoirs is a challenge.