A research and development project was conducted to study the use of preformed foams to improve cyclic steam stimulation (CSS). The field results showed benefits in incremental oil production, improvements in energy efficiency, and reduction in carbon intensity. Based on those outcomes, and with the goal of extending the production life of mature assets, the hybrid technology of CSS plus foam improvements was incorporated into the heavy oil field development plans of the Middle Magdalena Valley (MMV) basin in Colombia.

Pilot Results: 2019–2022

CSS maturity is one of the major challenges in the MMV. Many wells report more than 10 steam cycles, decreasing oil productivity, and a trend of shorter steam cycles (less than 10 months). Most injected steam drained the higher-flow-capacity intervals based on the permeability contrast within the pay zone and openhole completions. Therefore, the bullhead injection of preformed foam improvements implemented before the steam cycle was proposed as part of a conformance strategy. The main goal of the pilot test was to demonstrate the efficiency of the hybrid technology, extend the production life of steam cycles, increase oil recovery, and improve energy efficiency and carbon footprint.

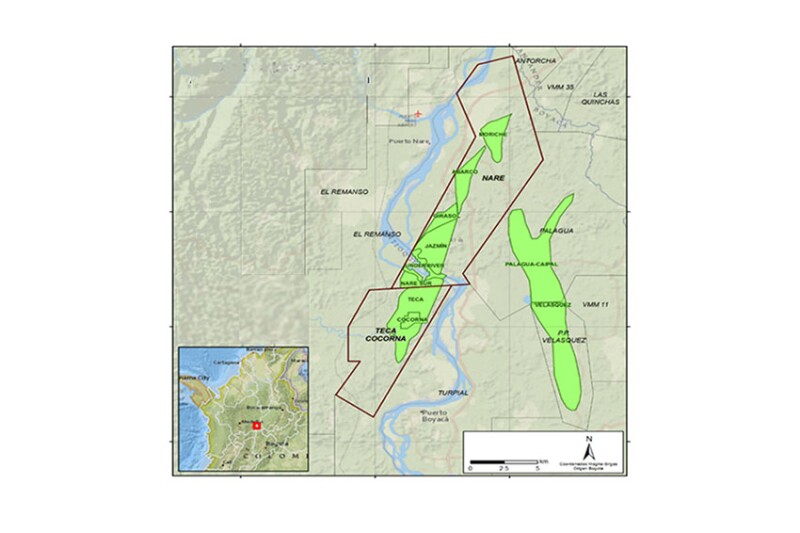

The CSS pilot was implemented in six wells of the Teca-Cocorna field (Fig.