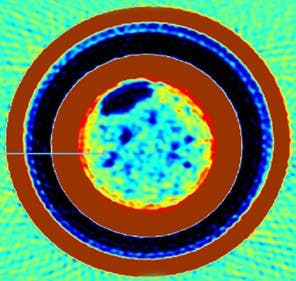

Tracerco’s Discovery subsea pipeline inspection system was designed to deliver accurate material results and distinguish between wax, sand, hydrate, asphaltene or scale deposition within a density differential as low as 0.03 g/cm3.

By gathering real-time data on a variety of pipeline integrity issues, including pipeline corrosion, erosion, pitting and wall thinning, modern inspection technologies enable operators to effectively determine the length of time a pipeline can be extended past its original design life. This can help eliminate the operating costs associated with designing a new section of pipeline, recommissioning, pipeline modification, and the time and risks associated with coating removal/reapplication and long and expensive vessel hire.

The introduction of advanced fast screening technology that can reduce overall scan time by up to 80% in some cases, which means operators can capture more data from a single pipeline inspection to help them improve and enhance the efficiency of existing pipeline models.

A clearer picture

Deepwater pipeline inspection systems are often deployed in conjunction with pipeline screening technology to locate blockages in subsea pipelines, which can be many miles in length. Accurately detecting the location of blockages caused by a buildup of deposits is an ongoing issue within pipeline operations. Modern technologies can offer flow assurance screening capabilities to identify areas for further investigation and are often deployed as a pre-cursor to the pipeline inspection system.

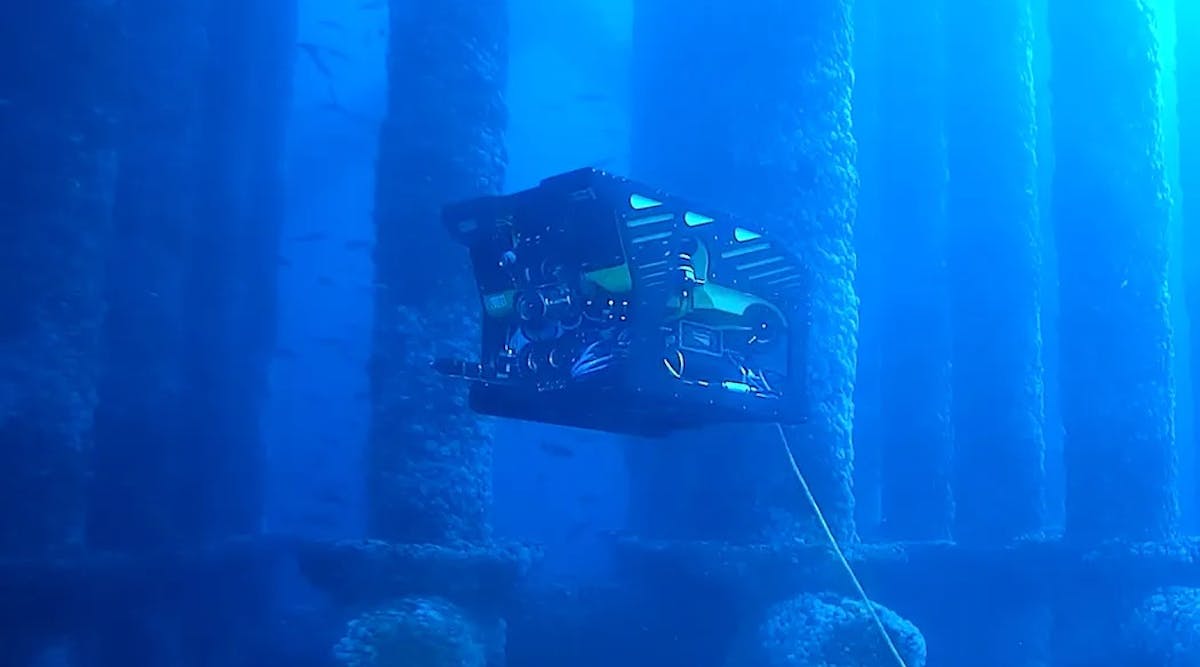

Advanced screening technologies, such as Tracerco’s Explorer, allow the rapid screening of pipelines for content and deposit buildup and can provide the capability to screen several kilometers of line at typical speeds of up to 100 m per hour without interruption to production. Non-intrusive with no requirement for pipeline preparations, these technologies can measure flow assurance from the outside of the pipeline, avoiding the need to remove protective coatings.

The most advanced screening systems are capable of being deployed at depths of up to 3,000 m (10,000 ft) and have been deployed to inspect a wide range of pipe diameters and systems including rigid coated or uncoated pipe, pipe-in-pipe, bundles and flexibles. They can provide a detailed pipeline profile by identifying the mean densities of contents and the volume of material based on measured densities, detecting the location of deposit buildup, measuring the density profile of the pipeline, and analyzing any detected anomalies.

Once the screening system has located any suspected blockage, the Discovery inspection system can be deployed to accurately characterize the precise type and scope.

Empowering data-driven decisions

Combining screening and inspection technologies together in a single process enables deepwater pipeline operators to obtain a much greater understanding of their asset’s integrity and flow performance. It can allow the scheduling of preventative maintenance programs, deliver insights for operators to engineer the most appropriate solutions, and support informed decisions on how to extend the lifespan of the pipeline past its original design envelope. By identifying potential issues in advance before they become major problems, this approach avoids the retrospective requirement to design a new pipeline section or undertake any pipeline modifications or recommissioning work.

Continuous innovation

As the oil and gas industry considers exposure to more challenging and deeper environments, the continuous development of new technology will be essential in supporting performance improvements. As exploration and production go deeper, pipelines will likely have to overcome even greater issues than at present when it comes to integrity and flow assurance. Being able to scan and inspect these assets as accurately and as quickly as possible while allowing production to continue will enable operators to make critical informed decisions, safely and efficiently.

Great strides have been made in the screening and inspection of deepwater pipelines, making what may have once been regarded as impossible now possible. However, the industry must continue to push the boundaries of products and services in the pipeline inspection sector to solve the seemingly impossible problems of the future.

About the author: Jim Bramlett is the commercial manager, Americas, with Tracerco.