"So the tool in its very early instances was qualified using a bespoke test jig, which we [DeltaTek] manufactured," Horn said, before reviewing the overall output results. "We manufactured a base plate, which had a rotary shoulder thread in the center of it with six circumferentially provided jackstands, where we could position compressive load cells mounted underneath hydraulic jacks, each one being 100 tons capacity. The load bearing components of the articulating tool were then mounted within this test jig, and a top plate with a pin adapter was made up to the upper rotary shoulder connection of the articulating tool, such that the only thing holding it together was the articulating load bearing components of the technology. We were able to then put internal ball pressure through the pin adapter, whilst for all intent and purposes, trying to pry apart the actual technology itself. This meant that we were able to test it with axial tension, articulation and internal bore pressure."

Results

Because the articulation tool effectively eliminated the highest bending moments that would otherwise act upon the landing string and wellhead running tools, it de-coupled the MODU from the conductor and surface casings run on the Auxiliary Well Center, enabling dual derrick operations that were not possible for the offset well, the authors of the paper explained.

The use of this technology saved multiple drift runs and more than 10 days of rig time for the Luiperd well compared with the 2014 offset.

"TotalEnergies had a lot of confidence to take it to this Luiperd application," Horn said during his presentation. "And the technology was used both on the conductor pipe and on the surface casing. On the surface casing, we have over two meters per second of current actually measured with over five meters of significant wave height. And the technology had nearly three days of suspension time with over 300 metric tons through it."

A maximum 317 MT (700,000 lb) of surface casing and landing string was suspended beneath the upper articulation tool. Both articulation tools were in continuous use for 75 hours with 4.3 knots of current and up to 5 m (16 ft) significant wave height (Hs).

"Although the Luiperd well was drilled in a unique offshore environment, similar conditions are prevalent across the world's deepwater basins, including the West of Shetland area in the UK and in the Gulf of Mexico where loop currents present a regular challenge," the paper states. "The subject Novel Articulation Tool can reduce operational risks and provide step change improvements in drilling performance for wells, which need to contend with strong surface currents and harsh weather environments."

Horn also noted that the team learned that the external sleeve wasn't able to actually fit through the bend restrictor in its original configuration, and the protector plates were damaged as a result. So, a redesign of a fully removable clamp sleeve was included in the subsequent runs, which has been the way that the technology has been run ever since.

"I'd like to thank the TotalEnergies petroleum team for using the technology [and] the Odfjell Drilling team," Horn said, concluding his presentation.

Recent news

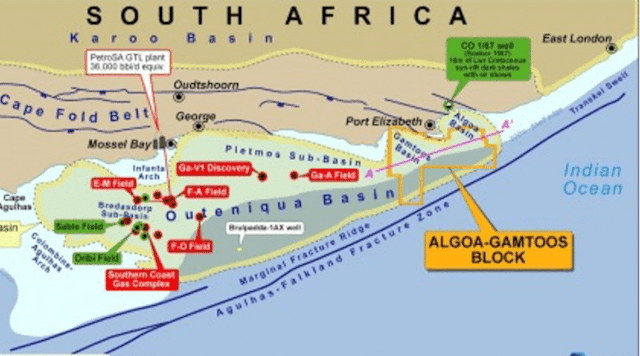

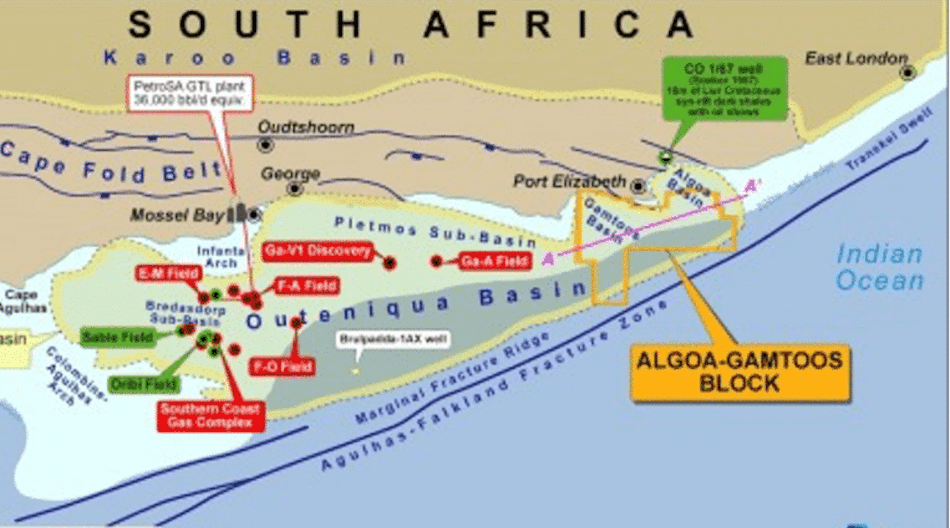

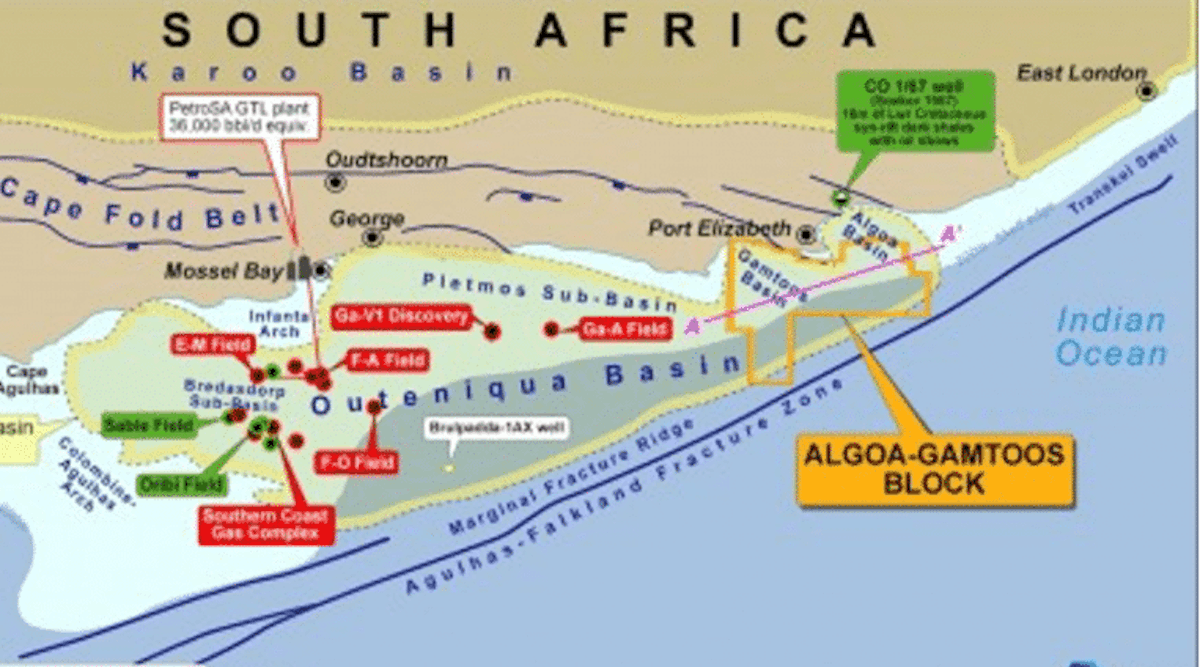

TotalEnergies and its co-venturers in Block 11B/12B offshore South Africa applied for a production right in late March. According to partner Africa Energy, they are considering either an early production system or a phased development of their two deepwater gas-condensate discoveries.

The early production system on the Luiperd discovery would accelerate the Block 11B/12B development timeline through using infrastructure on the adjacent block to supply gas to customers in Mossel Bay. It would also substantially reduce the capex to delivering first production on the block.

Africa Energy anticipates a full development of the Paddavissie Fairway would follow the early production system as the gas market expands in South Africa. Analysis of 2D and 3D seismic data has identified further prospectivity both in the fairway and to the east, reinforcing the view of large exploration upside across the block.

Africa Energy President and CEO Garrett Soden said the company expected operator TotalEnergies to finalize the development concept and gas offtake terms this year before receiving the production right approval in early 2024.

05.04.2023