化学驱油是提高采收率 (EOR) 的主要方法,用于回收岩石孔隙中的残余油。然而,注入的化学物质(如表面活性剂)必须可溶于低盐度和高盐度盐水、与储层离子相容并在高温下稳定。完整论文中描述的研究的主要目的是探索局部生产的表面活性剂在高温和高盐度储层环境中用于 EOR 的潜力。新型表面活性剂的设计和合成是使用绿色溶剂或无溶剂实现的。

化学 EOR 的重要性

由于一次采油只能采出15~20%的油气,因此在二次采油中通常采用注水或注气技术,以多采出15~20%的油气,并保持油田的原始压力。

化学驱油是提高采收率 (EOR) 的主要方法,用于回收岩石孔隙中的残余油。然而,注入的化学物质(如表面活性剂)必须可溶于低盐度和高盐度盐水、与储层离子相容并在高温下稳定。完整论文中描述的研究的主要目的是探索局部生产的表面活性剂在高温和高盐度储层环境中用于 EOR 的潜力。新型表面活性剂的设计和合成是使用绿色溶剂或无溶剂实现的。

由于一次采油只能采出15~20%的油气,因此在二次采油中通常采用注水或注气技术,以多采出15~20%的油气,并保持油田的原始压力。

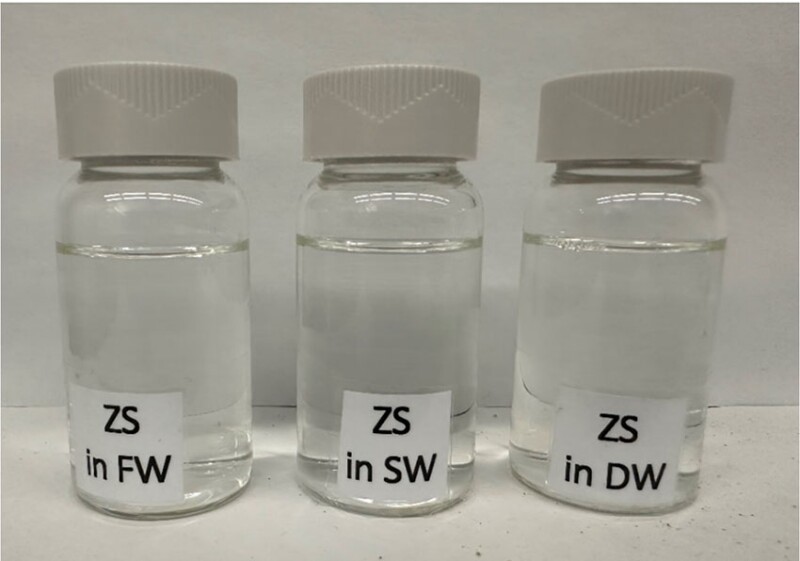

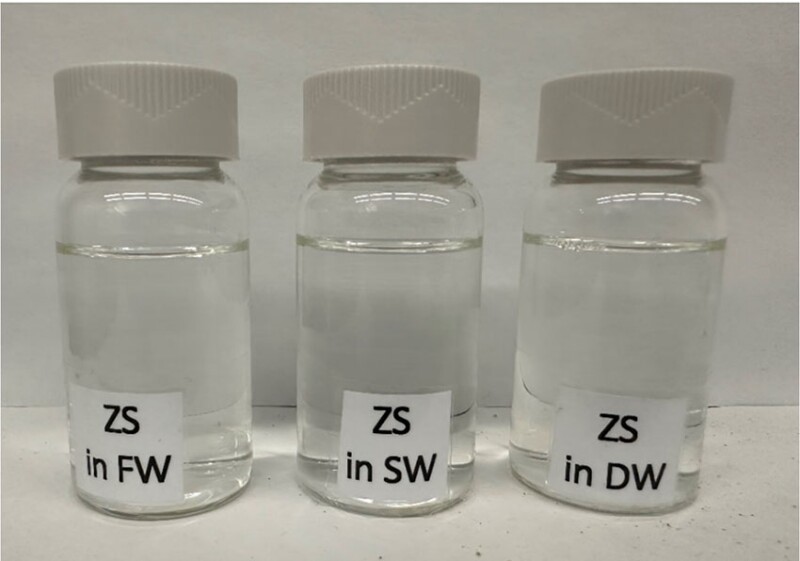

Chemical flooding is a major enhanced oil recovery (EOR) method for recovering residual oil within rock pores. Injected chemicals such as surfactant, however, must be soluble in low- and high-salinity brine, compatible with reservoir ions, and stable at elevated temperatures. The main objective of the study described in the complete paper is to explore the potential of locally produced surfactants for EOR in high-temperature and high-salinity reservoir environments. Design and synthesis of the new surfactants were achieved using green or no solvents.

Because only 15–20% of hydrocarbons can be extracted in the primary recovery stage, the waterflooding or gas-injection techniques usually are applied in the secondary recovery stage to extract 15–20% more oil and maintain the oilfield’s original pressure.