使用新兴的 3D 打印技术制造多组分复合结构,在石油和天然气设备的热塑性密封系统中实现了性能优化。定制的 3D 打印机配备了专利打印头,用于动态混合单个进料材料,并结合先进的打印规划程序,以制造新型热塑性结构。除了支持制造石油和天然气设备中快速响应的密封组件外,该技术还提供了一种在不增加密封组件尺寸或复杂性的情况下提高密封系统整体性能的方法。

介绍

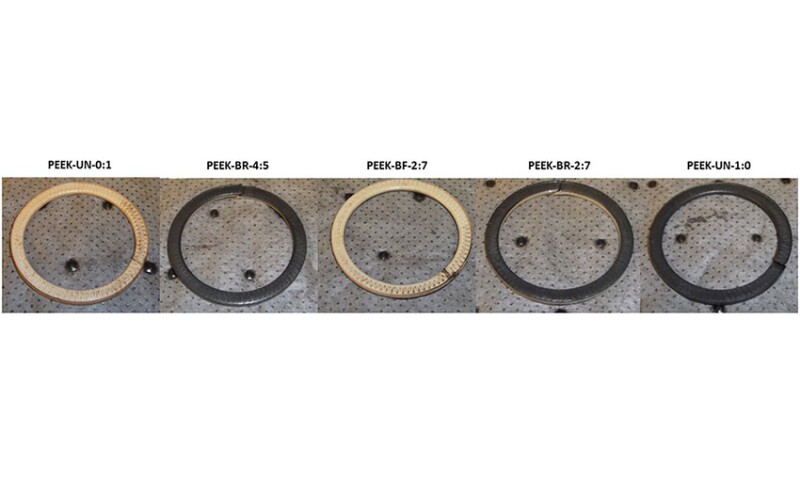

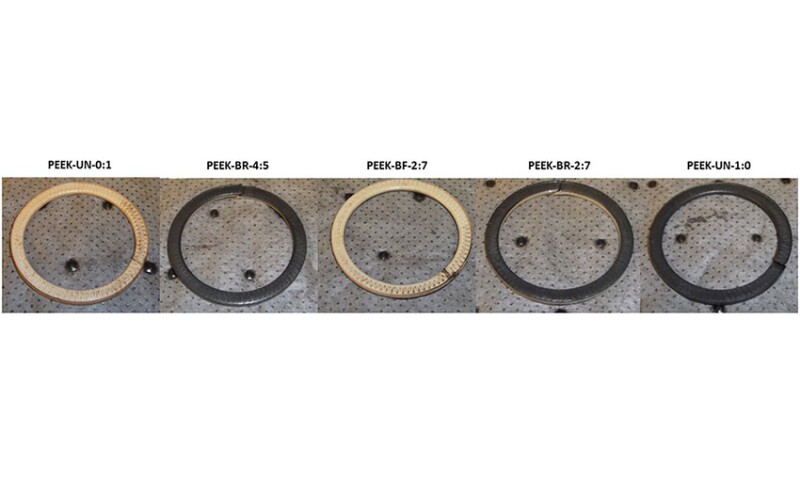

本研究旨在展示通过平垫圈 (FBUR) 结构创新来提高密封连接性能的潜力。采用组件级方法进行功能测试,并辅以更传统的材料分析。

使用新兴的 3D 打印技术制造多组分复合结构,在石油和天然气设备的热塑性密封系统中实现了性能优化。定制的 3D 打印机配备了专利打印头,用于动态混合单个进料材料,并结合先进的打印规划程序,以制造新型热塑性结构。除了支持制造石油和天然气设备中快速响应的密封组件外,该技术还提供了一种在不增加密封组件尺寸或复杂性的情况下提高密封系统整体性能的方法。

本研究旨在展示通过平垫圈 (FBUR) 结构创新来提高密封连接性能的潜力。采用组件级方法进行功能测试,并辅以更传统的材料分析。

Performance optimization was demonstrated in thermoplastic sealing systems for oil and gas equipment using emerging technologies in 3D printing to manufacture multicomponent composite structures. A custom 3D printer was equipped with a patented print head designed for dynamic mixing of individual feed materials and paired with advanced print-planning procedures to enable fabrication of novel thermoplastic structures. In addition to supporting fabrication of sealing components for rapid response in oil and gas equipment, this technique provides a means of improving the overall performance of sealing systems without an increase in the size or complexity of the sealing assembly.

The purpose of this study is to demonstrate the potential for performance improvements in sealing connections through innovation in flat-backup-ring (FBUR) architectures. A component-level approach to functional testing was taken with supplementation from more-traditional materials analysis.